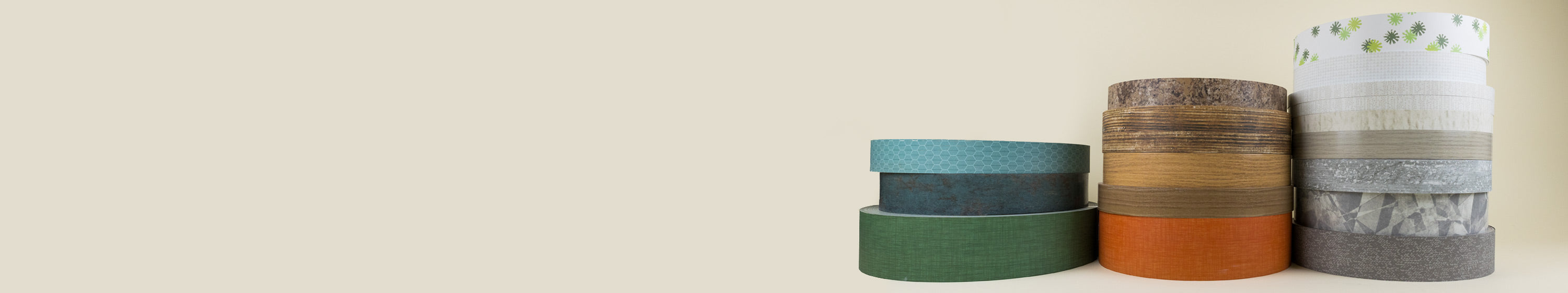

PVC Edgebanding

Laminate Brands

Popular

All

Abet Laminati

American Laminates

Arauco Prism

Arborite

Arclin

Arpa Industriale

Benjamin Moore

Chemetal

Dackor

Decor-Ative Specialities

Decotone Lamicolor

Duramar

Egger

Fenix

Finsa

Formica

Funder

Generics

Georgia Pacific

Interior Arts

KML

Kronospan

Lab Designs

Laminart

Lamitech

Lammates

LIRI Industriale

Nevamar

New Leaf

Northern Contours

Octolam/Octolux

Omnova

Panolam

Pionite

Roseburg Duramine

Roucke

Salt

Sherwin Williams

Benjamin Moore

Stevens Wood

Swiss Krono

Tafisa

Treefrog

Wilsonart

Uniboard

Design

Name

Brand

Code

Buy Online

Buy

Wilsonart L6447 Ribboned Satin Brushed Aged Gold

Ribboned Satin Brushed Aged Gold

Wilsonart

L6447

Recently Viewed

Laminate Brands We Match

Talk to an Edgebanding Tech

We're here to assist you with any questions, inquiries, or comments you may have. Our team is available Monday through Friday, from 8:00 am to 8:00 pm CST. Feel free to send us a message or give us a call. We're here for you!

Real humans. Right now. No hold music or voicemails

+1 (800) 622-9663Customer Service

service@framatech.comAccounting

accounting@framatech.comFrama-Tech IL

640 Darling Drive STE 102 Vernon Hills, IL 60061

8:30am - 5pm CST

Frama-Tech CA

2001 S Acacia Ave Compton, CA 90220

8:30am - 5pm PST

Frama-Tech TX

2000 E Arbrook Blvd Ste. 115, Arlington, TX 76014

8:30am - 5pm CST